Information

Teleflex Medical is a global provider of medical technologies, designed to improve the health and quality of people’s lives. Teleflex Medical OEM in Annacotty, Limerick was established in 1983 and currently employs 380 employees. This year we are celebrating 40 years in business.

Teleflex Medical OEM supports industry leaders in the design and manufacturing of medical devices with expertise that improves speed, flexibility, and value. Our portfolio is diverse, with our primary focus on Catheter and Tubing development, as well as testing and manufacturing. We at Teleflex pride ourselves on our key skills of extrusion capabilities, used to create a variety of tubing sizes and wall thicknesses, from concept development stage right up to the stage of a products manufacturability. The tubing that is produced in Limerick goes on to be used in IV catheters, diagnostic angiographic catheters and for delivering devices such as radiology stents. Our products are used by medical professionals every day in medical clinics and hospitals worldwide! Teleflex employees are united in the common understanding that what we do each day makes a crucial difference to people’s lives.

Careers at Teleflex:

There are endless career opportunities at Teleflex.

Engineering:

The engineers at Teleflex Medical OEM provide engineering support to manufacturing, new product development and new technology development activities taking place within the Limerick site. Specific focus area will be assigned based on business need. Our engineers are involved in various other activities such as

- Process characterisation

- DOE

- Production Support

- Validations

- FMEA

- Problem Solving

- Statistical Analysis

- Tooling management and design

- Equipment purchasing, commissioning, and installation.

Quality:

This role involves overseeing quality inspection, testing and release. Attention to detail is a key skill needed to carry out the following to a high standard:

- Quality input to new product design

- Transfer to manufacturing

- MRB’s

- Failure investigations

- Identifying and driving corrective actions,

- Verifying and validating implementation

- Documentation

- Communication with the customer.

Operations

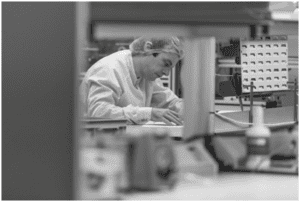

Our Manufacturing Team Members are responsible for manufacturing product components in the cleanroom environment. It goes without saying that the product we make must adhere to the required standards of target and productivity requirements. Health and safety adherence plays a huge role in the safe manufacturability of the finished product.